March 25, 2018

PAUL FRITTS

–––––––––––––––––––––––––––

Historically-Informed Organbuilding in the United States

March 25, 2018

PAUL FRITTS

–––––––––––––––––––––––––––

Historically-Informed Organbuilding in the United States

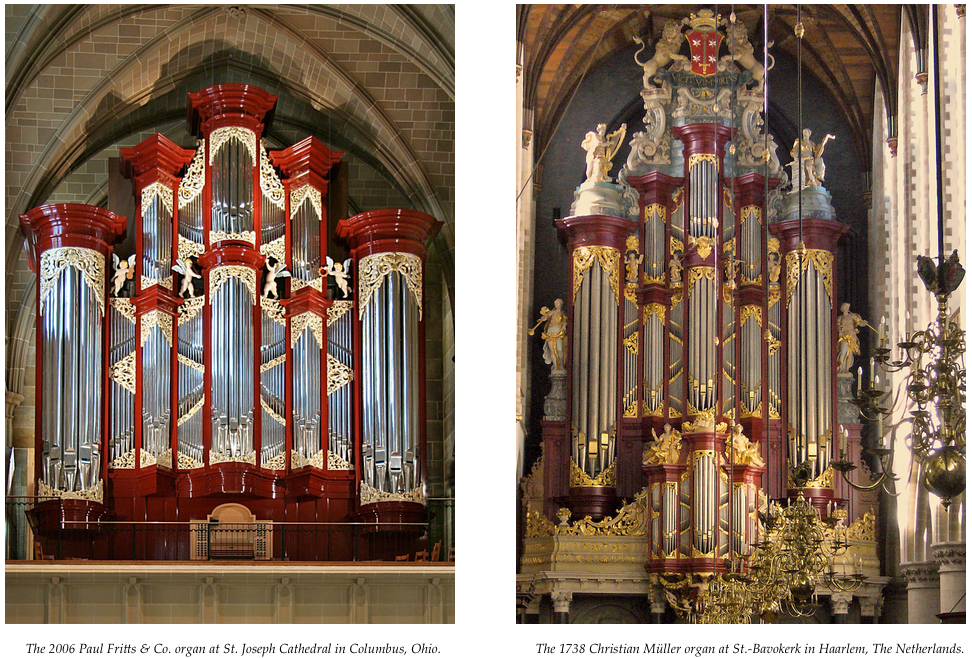

The 2006 Paul Fritts & Co. organ in Columbus, Ohio, at St. Joseph Cathedral.

The 2006 Paul Fritts & Co. organ in Columbus, Ohio, at St. Joseph Cathedral.

Introduction

In this interview with Vox Humana Associate Editor Jonathan Young, Paul Fritts discusses his incredible journey to becoming an organbuilder, the influence of historic northern European organs on his work, and various special techniques that he and his colleagues have rediscovered.

––––––––––––––––––––––––

Paul, many thanks for agreeing to this interview. How did you get started in organbuilding?

My father was professor of music at Pacific Lutheran University in Tacoma, Washington. He was also the son of a Lutheran pastor, who also taught him a lot about mechanical things and carpentry. During his years as a graduate student at the Eastman School of Music, he helped the organ technician, and became very interested in the organs’ mechanical aspects and maintaining them. When he took his first and only organist post at First Methodist Church in Tacoma (which he held for 36 years), the church had ordered a three-manual Æolian-Skinner to replace the two-manual (16’) Hook & Hastings. He actually liked the old organ quite a bit, but the Æolian-Skinner became, in his mind, the model of how organs should be. And it was a pretty good installation for that style of organ; there was a lot of sonority in the room and the placement was ideal.

I grew up in the home that he built, and he was always working on restoration projects (like a Ford Model A car). He also did some organ maintenance and later building, but always in the electric action realm. In many cases, he used supply house parts, all pre-voiced pipes, and I would help on some of the installations. By age 14, I was tuning mixtures and doing many other such tasks.

Independent of that, I was very interested in the organ, but I never had an interest in playing the organ (I did play the violin). However, I remember looking through his extensive library and being quite taken with photos of antique organs, partly because it was different from anything I had experienced in my upbringing. The whole idea of a free-standing case with working façades, carvings, and elaborate casework really caught my attention — there was something about it that signaled a different era that I didn’t know anything about. I had an interest in our roots (and always had a European car at one point or another).

So it was the visual aspect of the organs that caught your interest?

Yes, and he also had all the E. Power Biggs recordings. Those recordings made a big impression on people like John Brombaugh, me, and other organbuilders who grew up in that era. Some may remember the battle between E. Power Biggs and Virgil Fox as to what style an organ should be. My dad, of course, favored the Virgil Fox approach — with a remote console, and electric or electro-pneumatic action.

In the early 1970s, one of his former students and later organbuilding helpers, Roy Helms, completed a graduate degree in arts administration in Cincinnati, and one of his school projects was to put John Brombaugh’s books in order. Roy then immersed himself in these ideas, and would write letters to my father about these new ideas of organbuilding that he was exposed to and quite taken by, and my father would write back. In a sense, [my father] was really debating John Brombaugh about how organs should be built. Keep in mind that Brombaugh didn’t say “organs have to be built this way”, he was just explaining why he does what he does. One of the big points of contention was the placement of the console — my father argued that it had to be further away so the organist can hear what the listeners hear. And indeed, mechanical action consoles are tucked away at the foot of the organ, where you have to imagine what the audience is hearing.

How did you begin building your own instruments?

I went to college and sort of disconnected with my dad, in terms of “organ stuff.” I studied the violin, and I developed my own life and independence, and grew up (well, to a certain degree) and lived on my own and supported myself with a part-time job as a projectionist in a movie theater. And one day I got a call from my mother asking me to help my dad finish a project in Seattle. So I went up there on my days off and weekends to help finish this little electric action organ.

He had another contract after that for an electric-action unit organ for Good Shepherd Lutheran in Tacoma, and I wanted to apply some of the principles of organbuilding I’d been reading about — namely a free-standing case with a façade of 8’ principals, with everything behind that and reeds at the very back of the case. And so I designed this and built this case, and my father went along with it. That’s one of the last organs he was involved with.

My first organ that I played a big role in was in Anchorage, Alaska. Roy Helms was the state arts council director there and was active in the Lutheran church. One of the churches there asked him to build an organ, and he recommended my father’s company, saying that “his son Paul is involved and will bring some interesting aspects to the project.” So they signed the contract and I designed my first big organ of 26 stops. It was still electric action, as I wasn’t confident enough to tackle mechanical action yet, particularly in a difficult climate like that (I simply didn’t have the experience) — and that organ is still functioning and pretty well known in Anchorage. It has a free standing case and no swell.

As to my first mechanical action organ — Ralph Richards came on board to assist with voicing at the end of the Anchorage project. He and my dad had cooked up a project for First Methodist Church in Shelton, Washington becoming a mechanical action organ. I was intending on going down to Eugene to work in John Brombaugh’s shop, but I ended up not doing that because I knew that Ralph Richards and my dad would have an explosion and the whole thing would fall to pieces.

You had mentioned John Brombaugh a few times as a primary influence. Were there others?

The Shelton organ, because of Ralph Richards’s influence, is very “purist” in some respects, as far as he and I were able to make it “purist” or “historic.” For instance, the key and stop actions are all wooden. The Brombaugh influence there is that the case is very tightly packed. That is not necessarily historic, but a design game that we played, and frankly, it made it more difficult to build, voice, and tune the organ, because you’re opening and closing case doors, which has a big effect on things. Today we like to build organs with walkboards inside the case. But Brombaugh was a huge influence before all this because of his organ at Grace Episcopal Church in Ellensburg, Washington.

I was listening to a local organ radio program that Beth Barber did, and she had a recording of contemporary music played on the Ellensburg organ. I went down there for a preview of the organ in conjunction with an event in Portland celebrating some work that Charles Fisk did on a Hook & Hastings organ (that’s where I met him). I liked the sounds I heard. As it turned out, they weren’t necessarily historic sounds, but they were musically appealing, and different from what I’d grown up with.

Many organists like to characterize your style as Schnitger, or “old style,” even among the so-called “revivalist” organbuilders. But how would you characterize your style?

With any complex subject, be it voicing, historic style, whatever, the tendency is to glom onto certain aspects of it as a rule. So if I’m going to be labeled as a “builder of Schnitger-style organs,” you really have to know what a Schnitger organ is. The fact is that a lot of people haven’t even heard one outside of perhaps recordings, which is very different from going there and living it for a longer period of time than just a short visit on a tour. I’ve visited some historic organs up to four times, and each time I come away with a different bit of knowledge or connection to what they are.

Furthermore, you hear these things through the lens of repeated restorations and the effects of time. And each restoration takes the organ one step further from what it was. Some of these great organs have really been through hell, like St. Jacobi in Hamburg, which had a lot of pipe damage and crazy reworkings over the centuries, plus it was stored in a bunker during World War II. In his restoration, Jürgen Ahrend had to deal with all these things, and somehow from that create his version of what it “should be.”

One of the most interesting Schnitger organs is at Cappel. I would say that it probably has a great deal of original voicing in it, even though now it’s in a church that’s one quarter the size of the original and on much lower wind pressure. Additionally there are the effects of time and the change from meantone to equal temperament. These are all big factors that affect what you experience today hearing that organ. When you travel to northern Europe to understand the Schnitger approach, you have to imagine a lot — in this case, “what did this organ sound like on higher wind pressure in a larger room?” What we do hear is fullness and sweetness at the same time. We find speech without killed tone. And I believe that was highly sought-after by builders of that time. This is partly because the organs were human-powered and simply couldn’t generate extremely high wind pressures.

Other things come into play —we recently have been sand-casting the pipe metal, which generally means that it cools much faster, and therefore the crystalline structure is much smaller. The behavior of the metal then changes in subtle ways, and we feel that this enables the pipes to spring to life a little faster. We like the effects — there’s less refinement you have to do to the pipes to make them sound really nice. They feel different, to hold them, there’s just something about the metal that’s different. Once we started doing it and started experiencing the results, we don’t have a problem with the extra cost.

One unique aspect of your shop is that you build only mechanical action instruments. Why is that?

That was a decision we made early on, and we’ve learned a lot about it since. The reason now is that it’s much more sensitive. When a human finger presses the key on a mechanical action organ, even quickly and aggressively, the action is still less intense than a pneumatic motor pulling the pallet open. It’s also a voicing decision. Pipes voiced for mechanical action actually come up to speech faster than on a pneumatic or electrically-operated chest. In electric action, pipes have to be voiced much more slowly so they don’t fly off into the octave harmonic.

The other factor is longevity and reliability. When we put preset registration systems in the organs, they’re piggybacked onto mechanical stop action [there is an in-line servomotor at each slider], so if the electric system fails, the stops can still function normally in the mechanical sense. In a sense, we have two stop actions. When we get called back to solve problems on our newer organs that have preset electrical systems, it’s very rarely a mechanical problem — it’s usually an electrical issue that has to be dealt with.

Many of your organs are also pumpable by foot so one could play them entirely without electricity. Is that mainly for historical reasons, or does that affect the sound of the organ?

Some of the big organs we’ve made more recently have multiple bellows, one-way valves, and levers to raise the bellows (which pulls air into them, and the air gets pushed into the organ as you’re raising the other bellows). We found that the mass of those levers and the one-way valves help the wind system be more substantial and more stable in a sense. So the tendency of the wind to have jitters is less, and yet there’s a subtle buoyancy to the wind that gives the sense that the organ is breathing in a musical way. Our Columbus organ, for instance, has four bellows devoted to the manuals and two to the pedal, and you can footpump the organ. Playing full organ there can keep someone pretty busy back there, but it’s doable.

Also, if the audience is told that the organ is being pumped by a person, there’s a psychological phenomenon that happens — the thing they’re experiencing is entirely human-powered (the only exception to that is that the preset system can still be operational). People then listen in a different way with that knowledge. But the main reason for doing it is for the behavior of the wind. I suppose you could add levers and so on to do it artificially. For organs like in Bloomington, Indiana, where there’s no option to footpump, there are still three bellows: one devoted to the pedal, and two connected to the manuals. They add a complexity to the system, with the bellows feeding into the main trunk in different places, but this makes the wind system behave with more stability. There we’ve also made larger cavities in the bellows, which stabilizes some of the little jitters you might get in the wind system.

Unlike many builders in the U.S., you also don’t use concussion bellows in the wind chest. Why is that?

We do have stabilizers that are activated by the stop knob labeled “Stabilizer.” The bellows are not sprung, they are weighted, so when the wind is being used, the bellows go down, and the pressure actually increases a little, rather than decreasing if springs were employed (tension is reduced as they go down). And of course, an entirely weighted bellows has more mass. Its ability to move quickly is reduced, and therefore you rely more on the volume of air in the system, the length of the trunks, the size of the palate boxes.

You can’t predict how wind systems are going to behave. In Bloomington, we had an issue with the winding — the Swell division is at the top of the case, and the Great in the mid portion. Each of those divisions are winded separately; different trunks feed to the main trunk, which is connected to the bellows. There was bad communication between them, and so we ran connecting trunks between the two divisions at the two ends; doing that created a loop that increased the volume of the wind and solved the problem completely. That was an idea that I got from the Cappel organ. Don’t underestimate the knowledge and sophistication of the early builders.

Your organs, especially in terms of their look, are similar to Schnitger and other builders, who were Lutheran, but in recent years, you’ve constructed organs for large Roman Catholic churches (Columbus, Rochester, Notre Dame). What do you take into consideration when designing a case?

My job is to make an organ that looks as though it belongs in the building. A comment I get from members of congregations about our organs is that “it looks like it’s always been there, as if it always belongs,” which is very gratifying to hear. For me, the organ case has to have a good proportion, work musically, in terms of how the interior components are arranged (divisions, etc.), and the musical requirements need to be fulfilled. All this needs to be coordinated with the visual and mechanical aspects as well.

But back to making it beautiful and appropriate: I see no problem drawing upon the very best examples we have of past times. Steve Jobs said at one point, “Good artists copy. Great artists steal.” What I take away from that is, a good idea is a good idea — I don’t care where it comes from. But there are two cases I’ve designed entirely from scratch: Gethsemane Lutheran in Seattle, where they rejected a historic-inspired case, and St. Philip Presbyterian in Houston. I didn’t think a strictly historic case would work there, even though they were open to that. So we started with a box, and divided it into historically-appropriate sections, and then I included elements that indicated that the organ visually had its foot in some sort of historical place of integrity.

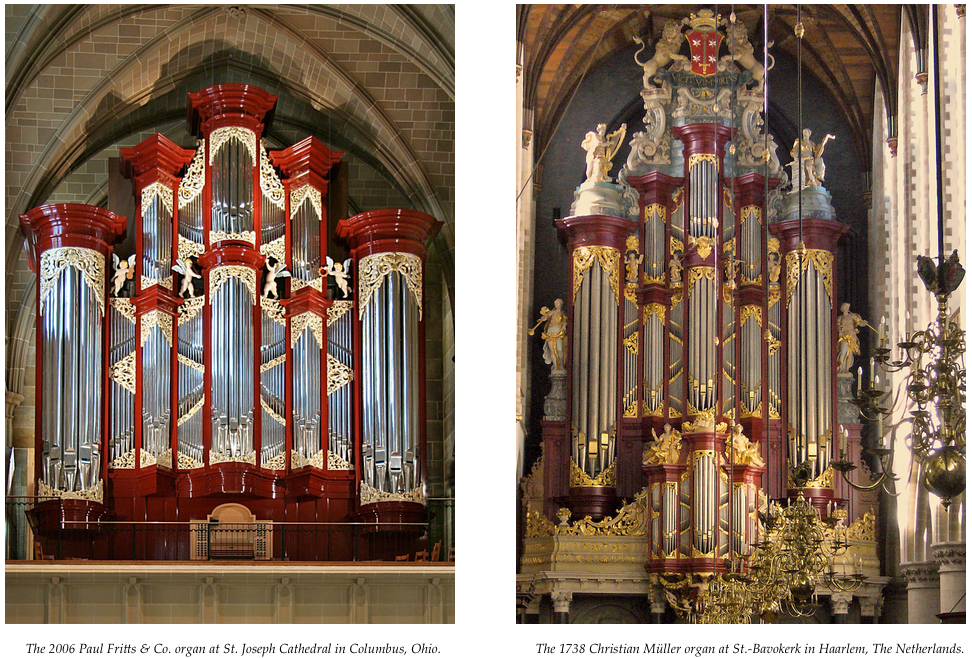

The case in Columbus was a challenge. We modeled it after the main case of the Bavokerk [in Haarlem], and adapted it for a very different gallery situation, and without a Rückpositiv. The problem in Columbus is that the gallery is quite high, so the space for the organ is rather short. I had to take the basic ideas of the Bavokerk case and alter them for my design and do it in a way that would retain the integrity of how all the various elements from Bavokerk are coordinated to remain intact. That means mastering the relationships of the curved moldings, vertical styles, carvings, pipes, etc. All of that has to be totally nailed, otherwise you have gaps, and it takes a tremendous amount of skill. I’m very happy with how it turned out.

We can’t just copy cases — it’s not copying at all — we’re literally creating something new from a basic concept we look at in a photograph. We don’t go measure these cases, we do a photographic study of proportion. Once you’ve decided which pipes go in the facade, which pipes play (which are dummies), how you wind them, the interior layout of the chests in relation to the front — everything has to be really carefully designed. I’d say building in a historic style is actually a lot more complex and demanding than building in the contemporary style.

So the same is true for the specification of the organ, from a historical perspective? How do you adapt that style for modern use? For instance, many of your organs have swell boxes.

I don’t think we could build a large organ today that didn’t have a swell box, preset system, or modern action that’s built to be as responsive and light as possible given the winding requirements. We’re building modern organs, but I think that adding the layer of complexity of a historic approach to the visual and tonal design really enhances our work. It leads us further into the realm of something more artistic. It makes building the organs much more challenging, but much more enjoyable as well. I have to get back to something Jürgen Ahrend said, “when curves go in, the profits go out.” But once you’ve developed methods of laying out segmented or rounded towers and the means of building that efficiently, then doing it again in a different context is much more feasible.

Of the organs you’ve built, have you found any one to be particularly challenging or interesting?

When you leave any project, you try very hard to make everything work to its potential. I think one big factor that impacts our work the most that we sometimes have little or no control over is the acoustical environment. In a rather dry but friendly space, such as here in Bloomington, you can work a certain amount of magic, but in a really reverberant nave like in Columbus, things move to a whole different level. To top things off there, the nature of the acoustics is such that more than reverberation, you have very strong, slightly reduced in speed, side wall reflections — milliseconds delayed. This contributes to a tremendous feeling of envelopment, which doesn’t happen often in spaces. You feel like you’re surrounded in the sound field, and it’s the same feeling you get in the great concert halls like the Concertgebouw in Amsterdam and Boston Symphony Hall. So we get a very heroic effect in Columbus that we’ve never experienced anywhere else. The cathedral in Rochester is a wonderfully reverberant space as well, but the side pillars are so thick that they eliminate side wall reflections, so you get a really strong drop off in sound as you move away. In that case, I opted not to push the organ, but to just let that happen, because I think an overly intense, pushed organ would be much less friendly than what we’ve done there.

Where do you think the future in this industry is headed, and where should organ design go?

The Bloomington organ is closely tied to the fact that this is a university town, and the university has a very strong organ department, and one of the professors [Christopher Young] is the organist here. Many of our projects are connected or related to universities in some way, but others aren’t. And this low pressure, less intense, more colorful yet full tonal approach does tie in very much to the musically untrained person in the congregation, whose musical experience doesn’t necessarily include the organ or even classical music. So I think about an approach that includes these people, because they’re paying for the organ, they’re living with it, and being led by it.

That’s one reason I’m attracted to the Schnitger ideal. Part of what he was doing was creating a tonal approach based on the work that he grew up with that could be more easily mass-produced. He built more than 100 organs in a time when builders often had a lifetime output of maybe 15–25, and some of [Schnitger’s] 100+ organs were large four-manual organs. His and our tonal approach is to make the pipes a certain way with certain metal, with certain ways of mouthing and thickness, using sand-cast metal; those pipes are then prepared, voiced, and soldered a way so they can leave the shop somewhat voiced and be planted in an organ, and the pressure can be adjusted up and down according to what sounds good in the space. Everything is gone through quickly, tuned, and we’re out of there, which seems to be what Schnitger did. This is documented by the fact that they hired pumpers during the installations. Part of that is enabled by lower intensity. Yet the tonal nature, the structure of the harmonics and harmonic quality would still allow them to carry through the space and be heard — the kind of sound that can lead a congregation without knocking them over the heads.

And so relating to the congregation is important — making them happy with what they’ve got, and ultimately touching them in a way they didn’t know was possible. It’s always good to experience that from people who are not really in music. We don’t want to build just for the few who have travelled and know intimately how organs work, sound, and are voiced. All that’s good, but most of the people who experience an organ in a recital or church are coming from a whole different place, and we do want to relate to them. I think that is a key to the future.

Another key to the future is that if you do quality work, there will always be a market for it. If you can’t keep the quality on a high level, it’s not going to last. We can only do the best we can, and let the future take its course. A burning question now is what’s the future of the church, and what’s the future of university organ departments? It really does relate to the ability of those in charge to generate enthusiasm and knowledge for the craft of playing and building — to keep pushing those boundaries higher, and also work to relate to the audiences, especially to those who don’t know all these things.

––––––––––––––––––––––––

Since the founding of the company in 1979,

Recent work has reflected a desire to expand further the range of the instruments while maintaining high musical standards within a meaningful and useful style. There are currently seven craftsmen working with Paul and all share a personal commitment to achieving superior craftsmanship within each instrument. All design work and construction of the thousands of components that make up an organ (except for the electric blowers and electronic pre-set systems) is done in-house from carefully selected raw materials. The establishment of the pipe shop in 1983 completed this vision for the company enabling detailed control of every aspect of the organs’ tonal makeup.

The views and opinions expressed in this article are those of the author, and do not necessarily reflect the position of Vox Humana.